FLASHPor Project

What if it was possible to replace the first long porcelain firing by a process of a few minutes?

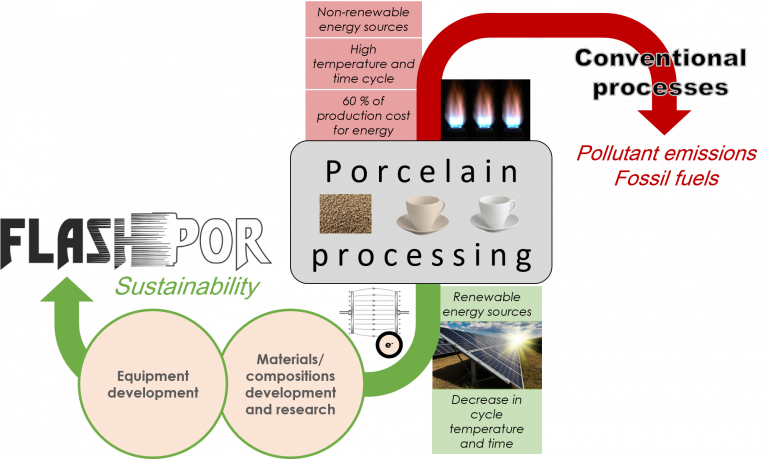

This is the question we intend to answer through the FLASHpor project, through which we will investigate, develop and validate the use of an alternative, innovative and environmentally more sustainable technology for porcelain sintering during the first firing/biscuit process – FLASH technology.

Conventional Porcelain Sintering Process

Aiming to ensure porcelain’s unique properties, two or three firings (white or decorated porcelain) are required throughout the process for extended times (over 6 hours) and high temperatures (≈ 1000oC, in the first firing/biscuit; over 1350oC ,in the second firing). Despite all efforts to ensure an optimised process, which does not compromise the environment, this one is still powered by fossil fuels, by being the biscuit cycle able to represent around 15% of the plant’s total energy consumption.

How can FLASH technology turn the process into something more sustainable?

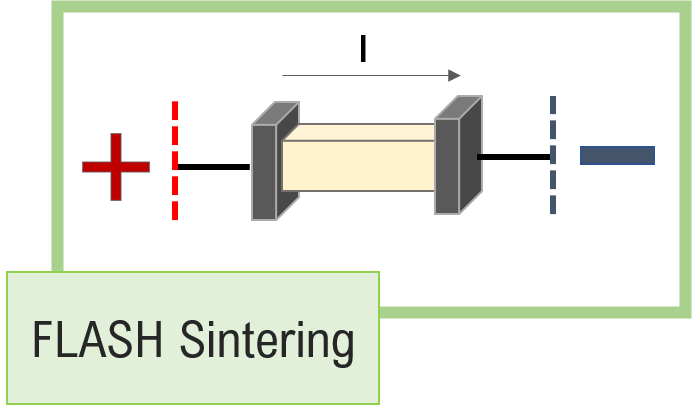

FLASH technology uses an electric field as the driving force for densification, thus allowing to decrease the dependence on temperature during the porcelain’s firing process. This will be applied to the biscuit process, thus allowing for a more sustainable sintering cycle (decrease in temperature and firing time).

Project Goals

Ceramic bodies’ R&D with suitable compositions for firing, by using FLASH technology

R&D of FLASH sintering kilns, namely with the construction of a laboratory test’s kiln and its scale-up, into a second (pilot) kiln for porcelain’s firing

Studies for the applicability and industrial feasibility of porcelain’s FLASH sintering process

Project Expectations

- Increase of the Process’ Environmental Sustainability

- Significant Reduction on Production Costs

- Increase of the Productive Rate

- Increased Competitiveness of the Companies in the Sector

Check out the video here!